Space News space history and artifacts articles Messages space history discussion forums Sightings worldwide astronaut appearances Resources selected space history documents |

If you have previously registered, but forgotten your password, click here.

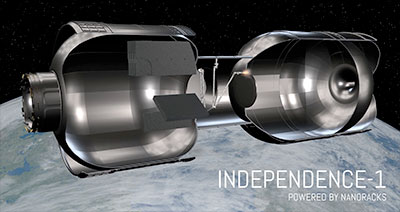

Decades of advances in robotics will allow Nanoracks to manufacture our outposts in space. MDA US Systems has analyzed the robotic systems required build this structure in space. Made for customer needs - whether as a home, satellite deployment venue, or a research hub - we're ready for you. This cost-saving technique will revolutionze space exploration. Independence-1 Our first outpost will be INDEPENDENCE-1. The Nanoracks Space Outpost Program which was chosen to be part of NASA's NextSTEP effort, successfully conducted a comprehensive feasibility study evaluating the conversion of rocket upper stages into habitats. This innovative approach offers a pathway that is more affordable and involves less risk than fabricating modules on the ground and subsequently launching them into orbit.  Our team proposed demonstrating this revolutionary, low-cost concept via the conversion of a Centaur rocket upper stage which can either be attached to the International Space Station or serve as a free-flying outpost. Our first outpost, INDEPENDENCE-1, will serve as a proving ground for a variety of private sector activities leading to a new era in commercial low-Earth orbit (LEO) utilization. After being proven in LEO, the Wet Lab approach can be used to create deep space habitats from any future rocket upper stages, including the Space Launch System's upper stage, which would provide a substantial amount of volume and capability for beyond LEO human exploration missions to the Moon, Mars, and beyond. | ||||||||

| Robert Pearlman | Nanoracks release by CEO Jeffrey Manber Nanoracks Announces In-Space Outpost Demonstration | |||||||