Aerojet Rocketdyne, ULA Announce Public-Private Partnership With USAF to Develop RD-180 Replacement EngineThe U.S. Air Force selected Aerojet Rocketdyne, a subsidiary of Aerojet Rocketdyne Holdings, Inc., and United Launch Alliance (ULA) to share in a public-private partnership to develop jointly the AR1 engine — an American-made rocket propulsion system.

The Air Force decision — coupled with a large internal investment in the AR1 engine — is a major step forward in ensuring that the U.S. has a domestically-built rocket engine to replace the Russian-built RD-180 engines currently used to launch many Pentagon payloads into orbit.

The total agreement is valued at $804 million with the U.S. Air Force investing two-thirds of the funding required to complete development of the AR1 engine by 2019.

"This award from the U.S. government demonstrates its support of AR1 and recognizes the priority of assured access to space for our critical national security assets," said Eileen Drake, CEO and President of Aerojet Rocketdyne. "The AR1 engine is the option with the least technical risk that allows the United States to quickly and efficiently transition off its use of Russian-supplied engines currently used on the Atlas V launch vehicle."

The work is expected to be completed no later than Dec. 31, 2019. The Air Force intends to initially obligate $115.3 million with Aerojet Rocketdyne and ULA contributing $57.7 million. The total potential government investment, including all options, is $536 million. The total potential investment by Aerojet Rocketdyne and its partners, including all options, is $268 million.

"AR1 will return the United States to the forefront of kerosene rocket propulsion technology," added Drake. "We are incorporating the latest advances in modern manufacturing, while capitalizing on our rich knowledge of rocket engines to produce a new, state-of-the-art engine that will end our reliance on a foreign supplier to launch our nation's national security assets."

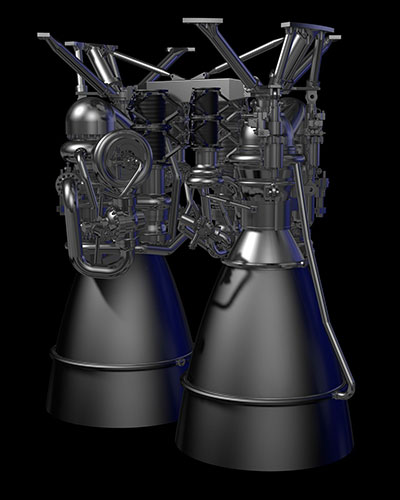

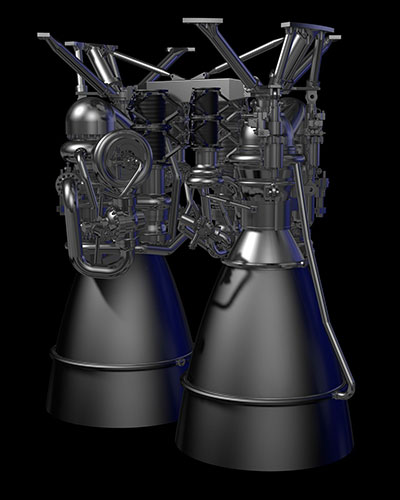

The liquid oxygen/kerosene-fueled AR1 booster engine uses an advanced oxidizer-rich staged combustion engine cycle and will be available for commercial sale to any U.S. launch provider. AR1 will be the nation's first domestically produced oxidizer-rich staged combustion kerosene engine.

According to Drake, "This engine will be available for use on the Atlas V, Vulcan and other launch vehicles currently in development."

"ULA is fully committed to transitioning as quickly and affordably as possible to a domestic engine," said ULA President and CEO Tory Bruno. "Our supplier, Aerojet Rocketdyne, is moving us toward one of two viable options with the excellent progress on the AR1 engine development."

Because of each company's strong commitment to ending reliance of the Russian RD-180 engine on the Atlas V, Aerojet Rocketdyne and ULA have been investing in AR1 ahead of a public-private partnership agreement. The U.S. Air Force, The Aerospace Corporation, NASA and other government and industry experts have been kept apprised of progress on the AR1 since its inception. Most recently, Aerojet Rocketdyne held a major design review for the AR1 program with all stakeholders. The AR1 passed with flying colors, allowing the team to proceed with design implementation.

Drake confirms, "AR1 remains on track for a flight-qualified engine delivery in 2019, which will fly in 2020."